Picture amplifiers are essential components in various electronic devices, including televisions, computers, and audio systems. These devices are used to enhance the quality of images and videos by increasing their brightness, contrast, and sharpness. The production process of picture amplifiers involves several steps, each of which is crucial in ensuring the quality and performance of the final product.

The mainstream production process of picture amplifiers typically begins with the design phase. During this phase, engineers and designers work together to create a detailed blueprint of the amplifier, including its circuitry, components, and specifications. The design phase also involves selecting the appropriate materials and components that will be used in the production of the amplifier.

Once the design phase is complete, the next step in the production process is prototyping. Prototyping involves creating a physical prototype of the amplifier based on the design specifications. This prototype is used to test the functionality and performance of the amplifier, as well as to identify any potential issues or improvements that need to be made.

After the prototype has been tested and approved, the production phase can begin. The production of picture amplifiers typically involves several key steps, including component assembly, circuit board fabrication, testing, and quality control.

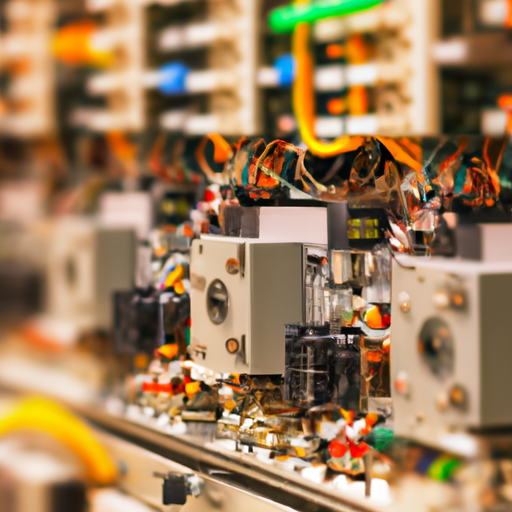

Component assembly is the first step in the production process, where the various components of the amplifier are assembled together to create the final product. This process involves soldering the components onto the circuit board, connecting wires, and ensuring that all components are properly aligned and secured.

Once the components have been assembled, the next step is circuit board fabrication. Circuit boards are essential components of picture amplifiers, as they provide the necessary connections and pathways for the electrical signals to travel through the amplifier. Circuit board fabrication involves etching the circuit patterns onto a blank circuit board, drilling holes for the components, and soldering the components onto the board.

After the circuit board has been fabricated, the next step in the production process is testing. Testing is a critical step in ensuring the quality and performance of the amplifier. During testing, the amplifier is connected to a test system that measures its performance, including its signal strength, frequency response, and distortion levels. Any issues or defects that are identified during testing are addressed and corrected before the amplifier is approved for production.

Quality control is the final step in the production process, where the finished amplifiers are inspected and tested to ensure that they meet the required specifications and standards. Quality control involves visual inspection of the amplifiers for any defects or imperfections, as well as testing their performance to ensure that they meet the required performance criteria.

In addition to the production process, there are also several factors that can impact the quality and performance of picture amplifiers. These factors include the quality of the materials and components used in the production process, the expertise and experience of the production team, and the quality control measures that are in place.

Overall, the production process of picture amplifiers is a complex and intricate process that involves several key steps, each of which is crucial in ensuring the quality and performance of the final product. By following a systematic and rigorous production process, manufacturers can produce high-quality picture amplifiers that meet the needs and expectations of consumers.

Picture amplifiers are essential components in various electronic devices, including televisions, computers, and audio systems. These devices are used to enhance the quality of images and videos by increasing their brightness, contrast, and sharpness. The production process of picture amplifiers involves several steps, each of which is crucial in ensuring the quality and performance of the final product.

The mainstream production process of picture amplifiers typically begins with the design phase. During this phase, engineers and designers work together to create a detailed blueprint of the amplifier, including its circuitry, components, and specifications. The design phase also involves selecting the appropriate materials and components that will be used in the production of the amplifier.

Once the design phase is complete, the next step in the production process is prototyping. Prototyping involves creating a physical prototype of the amplifier based on the design specifications. This prototype is used to test the functionality and performance of the amplifier, as well as to identify any potential issues or improvements that need to be made.

After the prototype has been tested and approved, the production phase can begin. The production of picture amplifiers typically involves several key steps, including component assembly, circuit board fabrication, testing, and quality control.

Component assembly is the first step in the production process, where the various components of the amplifier are assembled together to create the final product. This process involves soldering the components onto the circuit board, connecting wires, and ensuring that all components are properly aligned and secured.

Once the components have been assembled, the next step is circuit board fabrication. Circuit boards are essential components of picture amplifiers, as they provide the necessary connections and pathways for the electrical signals to travel through the amplifier. Circuit board fabrication involves etching the circuit patterns onto a blank circuit board, drilling holes for the components, and soldering the components onto the board.

After the circuit board has been fabricated, the next step in the production process is testing. Testing is a critical step in ensuring the quality and performance of the amplifier. During testing, the amplifier is connected to a test system that measures its performance, including its signal strength, frequency response, and distortion levels. Any issues or defects that are identified during testing are addressed and corrected before the amplifier is approved for production.

Quality control is the final step in the production process, where the finished amplifiers are inspected and tested to ensure that they meet the required specifications and standards. Quality control involves visual inspection of the amplifiers for any defects or imperfections, as well as testing their performance to ensure that they meet the required performance criteria.

In addition to the production process, there are also several factors that can impact the quality and performance of picture amplifiers. These factors include the quality of the materials and components used in the production process, the expertise and experience of the production team, and the quality control measures that are in place.

Overall, the production process of picture amplifiers is a complex and intricate process that involves several key steps, each of which is crucial in ensuring the quality and performance of the final product. By following a systematic and rigorous production process, manufacturers can produce high-quality picture amplifiers that meet the needs and expectations of consumers.