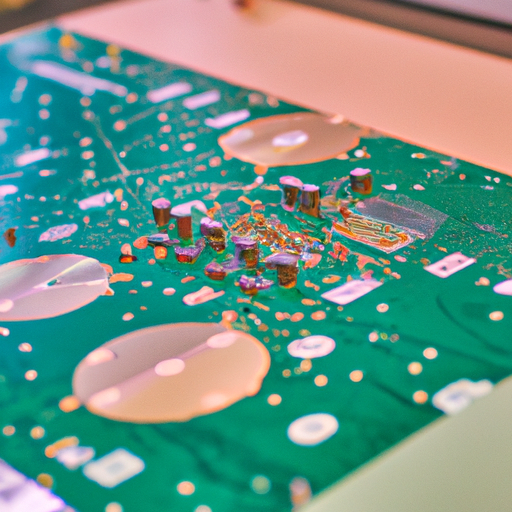

Screen amplifiers are an essential component in modern electronic devices, providing the necessary boost to the display signal for optimal viewing. As technology continues to advance, manufacturers are constantly innovating and improving their manufacturing processes to meet the increasing demand for high-quality screen amplifiers. In this article, we will explore some of the latest manufacturing processes used in the production of screen amplifiers.

One of the key advancements in screen amplifier manufacturing is the use of advanced materials and technologies. Manufacturers are now utilizing high-quality materials such as gallium nitride (GaN) and silicon carbide (SiC) to improve the performance and efficiency of screen amplifiers. These materials offer better thermal conductivity, higher breakdown voltage, and improved power handling capabilities, making them ideal for use in high-performance screen amplifiers.

In addition to advanced materials, manufacturers are also incorporating cutting-edge technologies such as 3D printing and nanotechnology into their manufacturing processes. 3D printing allows for the rapid prototyping and production of complex components, reducing lead times and costs. Nanotechnology, on the other hand, enables manufacturers to create smaller and more efficient screen amplifiers by manipulating materials at the atomic and molecular levels.

Another important aspect of screen amplifier manufacturing is the use of advanced manufacturing techniques such as flip-chip bonding and wafer-level packaging. Flip-chip bonding is a process in which the semiconductor die is directly bonded to the substrate, allowing for better thermal management and improved electrical performance. Wafer-level packaging, on the other hand, involves packaging multiple semiconductor dies on a single wafer, reducing the size and cost of the final product.

Furthermore, manufacturers are also focusing on improving the efficiency and sustainability of their manufacturing processes. This includes the use of renewable energy sources, such as solar and wind power, to reduce the carbon footprint of screen amplifier production. Additionally, manufacturers are implementing lean manufacturing principles to minimize waste and improve overall efficiency.

Overall, the latest manufacturing processes in screen amplifier production are focused on utilizing advanced materials and technologies, improving efficiency and sustainability, and reducing costs. By incorporating these advancements into their manufacturing processes, manufacturers are able to produce high-quality screen amplifiers that meet the demands of today's technology-driven world.

Screen amplifiers are an essential component in modern electronic devices, providing the necessary boost to the display signal for optimal viewing. As technology continues to advance, manufacturers are constantly innovating and improving their manufacturing processes to meet the increasing demand for high-quality screen amplifiers. In this article, we will explore some of the latest manufacturing processes used in the production of screen amplifiers.

One of the key advancements in screen amplifier manufacturing is the use of advanced materials and technologies. Manufacturers are now utilizing high-quality materials such as gallium nitride (GaN) and silicon carbide (SiC) to improve the performance and efficiency of screen amplifiers. These materials offer better thermal conductivity, higher breakdown voltage, and improved power handling capabilities, making them ideal for use in high-performance screen amplifiers.

In addition to advanced materials, manufacturers are also incorporating cutting-edge technologies such as 3D printing and nanotechnology into their manufacturing processes. 3D printing allows for the rapid prototyping and production of complex components, reducing lead times and costs. Nanotechnology, on the other hand, enables manufacturers to create smaller and more efficient screen amplifiers by manipulating materials at the atomic and molecular levels.

Another important aspect of screen amplifier manufacturing is the use of advanced manufacturing techniques such as flip-chip bonding and wafer-level packaging. Flip-chip bonding is a process in which the semiconductor die is directly bonded to the substrate, allowing for better thermal management and improved electrical performance. Wafer-level packaging, on the other hand, involves packaging multiple semiconductor dies on a single wafer, reducing the size and cost of the final product.

Furthermore, manufacturers are also focusing on improving the efficiency and sustainability of their manufacturing processes. This includes the use of renewable energy sources, such as solar and wind power, to reduce the carbon footprint of screen amplifier production. Additionally, manufacturers are implementing lean manufacturing principles to minimize waste and improve overall efficiency.

Overall, the latest manufacturing processes in screen amplifier production are focused on utilizing advanced materials and technologies, improving efficiency and sustainability, and reducing costs. By incorporating these advancements into their manufacturing processes, manufacturers are able to produce high-quality screen amplifiers that meet the demands of today's technology-driven world.