Air conditioner amplifiers are an essential component of any air conditioning system, as they help to regulate the flow of electricity and ensure that the system operates efficiently. These amplifiers are responsible for controlling the speed of the compressor motor, which in turn regulates the temperature of the air being circulated throughout the space. In this article, we will explore the common production processes for air conditioner amplifiers, including the materials used, the manufacturing techniques employed, and the quality control measures implemented to ensure a reliable and high-performing product.

Materials Used in Air Conditioner Amplifier Production

The production of air conditioner amplifiers begins with the selection of high-quality materials that are capable of withstanding the rigors of daily use and providing reliable performance over an extended period of time. The most common materials used in the production of air conditioner amplifiers include:

1. Printed Circuit Boards (PCBs): PCBs are essential components of air conditioner amplifiers, as they provide the electrical connections necessary for the amplifier to function properly. These boards are typically made of fiberglass or other composite materials, with copper traces etched onto the surface to create the necessary circuitry.

2. Electronic Components: Air conditioner amplifiers contain a variety of electronic components, including resistors, capacitors, transistors, and integrated circuits. These components are carefully selected for their specific functions and are soldered onto the PCB to create the amplifier circuit.

3. Enclosures: The amplifier circuit is typically housed in a protective enclosure made of plastic or metal. This enclosure helps to protect the circuit from dust, moisture, and other environmental factors, ensuring that the amplifier operates reliably in a variety of conditions.

Manufacturing Techniques for Air Conditioner Amplifier Production

The production of air conditioner amplifiers involves a series of manufacturing processes that are designed to ensure the quality and reliability of the final product. Some of the most common manufacturing techniques used in the production of air conditioner amplifiers include:

1. Surface Mount Technology (SMT): Surface mount technology is a popular manufacturing technique used to assemble electronic components onto PCBs. In this process, electronic components are placed onto the surface of the PCB and soldered in place using a reflow oven. SMT allows for high levels of precision and accuracy, resulting in a reliable and high-performing amplifier circuit.

2. Automated Assembly: Many manufacturers use automated assembly equipment to streamline the production process and increase efficiency. These machines are capable of placing and soldering electronic components onto PCBs at a much faster rate than manual assembly, reducing production time and costs.

3. Quality Control: Quality control is an essential part of the production process for air conditioner amplifiers, as it helps to ensure that each amplifier meets the necessary performance and reliability standards. Manufacturers use a variety of testing methods, including functional testing, thermal testing, and environmental testing, to verify the quality of each amplifier before it is shipped to customers.

Quality Control Measures for Air Conditioner Amplifier Production

Quality control is a critical aspect of the production process for air conditioner amplifiers, as it helps to ensure that each amplifier meets the necessary performance and reliability standards. Manufacturers implement a variety of quality control measures to verify the quality of each amplifier and identify any potential issues before they reach the customer. Some of the most common quality control measures used in the production of air conditioner amplifiers include:

1. Functional Testing: Functional testing is a crucial step in the production process, as it helps to verify that the amplifier circuit is functioning correctly and meeting the specified performance requirements. Manufacturers use specialized testing equipment to simulate real-world operating conditions and ensure that the amplifier responds appropriately to changes in temperature and load.

2. Thermal Testing: Thermal testing is used to evaluate the performance of the amplifier circuit under different temperature conditions. Manufacturers subject the amplifier to extreme temperatures to assess its thermal stability and ensure that it can operate reliably in a variety of environments.

3. Environmental Testing: Environmental testing is conducted to evaluate the durability of the amplifier circuit and its ability to withstand harsh environmental conditions. Manufacturers subject the amplifier to humidity, vibration, and other environmental factors to ensure that it can perform reliably over an extended period of time.

In conclusion, the production of air conditioner amplifiers involves a series of manufacturing processes that are designed to ensure the quality and reliability of the final product. By using high-quality materials, employing advanced manufacturing techniques, and implementing rigorous quality control measures, manufacturers can produce air conditioner amplifiers that provide reliable performance and efficient operation for years to come.

Air conditioner amplifiers are an essential component of any air conditioning system, as they help to regulate the flow of electricity and ensure that the system operates efficiently. These amplifiers are responsible for controlling the speed of the compressor motor, which in turn regulates the temperature of the air being circulated throughout the space. In this article, we will explore the common production processes for air conditioner amplifiers, including the materials used, the manufacturing techniques employed, and the quality control measures implemented to ensure a reliable and high-performing product.

Materials Used in Air Conditioner Amplifier Production

The production of air conditioner amplifiers begins with the selection of high-quality materials that are capable of withstanding the rigors of daily use and providing reliable performance over an extended period of time. The most common materials used in the production of air conditioner amplifiers include:

1. Printed Circuit Boards (PCBs): PCBs are essential components of air conditioner amplifiers, as they provide the electrical connections necessary for the amplifier to function properly. These boards are typically made of fiberglass or other composite materials, with copper traces etched onto the surface to create the necessary circuitry.

2. Electronic Components: Air conditioner amplifiers contain a variety of electronic components, including resistors, capacitors, transistors, and integrated circuits. These components are carefully selected for their specific functions and are soldered onto the PCB to create the amplifier circuit.

3. Enclosures: The amplifier circuit is typically housed in a protective enclosure made of plastic or metal. This enclosure helps to protect the circuit from dust, moisture, and other environmental factors, ensuring that the amplifier operates reliably in a variety of conditions.

Manufacturing Techniques for Air Conditioner Amplifier Production

The production of air conditioner amplifiers involves a series of manufacturing processes that are designed to ensure the quality and reliability of the final product. Some of the most common manufacturing techniques used in the production of air conditioner amplifiers include:

1. Surface Mount Technology (SMT): Surface mount technology is a popular manufacturing technique used to assemble electronic components onto PCBs. In this process, electronic components are placed onto the surface of the PCB and soldered in place using a reflow oven. SMT allows for high levels of precision and accuracy, resulting in a reliable and high-performing amplifier circuit.

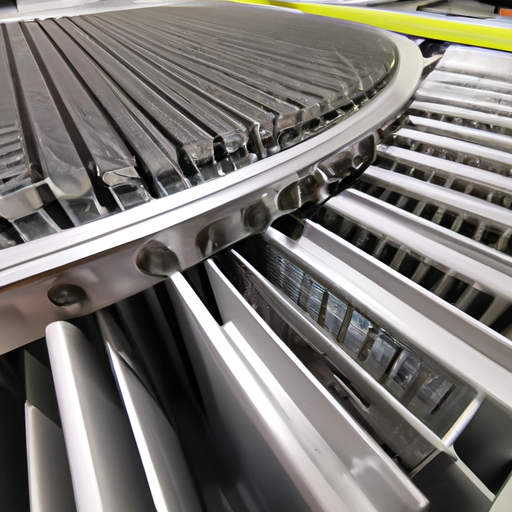

2. Automated Assembly: Many manufacturers use automated assembly equipment to streamline the production process and increase efficiency. These machines are capable of placing and soldering electronic components onto PCBs at a much faster rate than manual assembly, reducing production time and costs.

3. Quality Control: Quality control is an essential part of the production process for air conditioner amplifiers, as it helps to ensure that each amplifier meets the necessary performance and reliability standards. Manufacturers use a variety of testing methods, including functional testing, thermal testing, and environmental testing, to verify the quality of each amplifier before it is shipped to customers.

Quality Control Measures for Air Conditioner Amplifier Production

Quality control is a critical aspect of the production process for air conditioner amplifiers, as it helps to ensure that each amplifier meets the necessary performance and reliability standards. Manufacturers implement a variety of quality control measures to verify the quality of each amplifier and identify any potential issues before they reach the customer. Some of the most common quality control measures used in the production of air conditioner amplifiers include:

1. Functional Testing: Functional testing is a crucial step in the production process, as it helps to verify that the amplifier circuit is functioning correctly and meeting the specified performance requirements. Manufacturers use specialized testing equipment to simulate real-world operating conditions and ensure that the amplifier responds appropriately to changes in temperature and load.

2. Thermal Testing: Thermal testing is used to evaluate the performance of the amplifier circuit under different temperature conditions. Manufacturers subject the amplifier to extreme temperatures to assess its thermal stability and ensure that it can operate reliably in a variety of environments.

3. Environmental Testing: Environmental testing is conducted to evaluate the durability of the amplifier circuit and its ability to withstand harsh environmental conditions. Manufacturers subject the amplifier to humidity, vibration, and other environmental factors to ensure that it can perform reliably over an extended period of time.

In conclusion, the production of air conditioner amplifiers involves a series of manufacturing processes that are designed to ensure the quality and reliability of the final product. By using high-quality materials, employing advanced manufacturing techniques, and implementing rigorous quality control measures, manufacturers can produce air conditioner amplifiers that provide reliable performance and efficient operation for years to come.